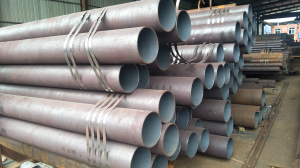

Pipe e chesang e kentsoeng e se nang seamless

Pipe ea tšepe e sa koaheloang e chesang

Li-tubes tsa tšepe tse se nang seamless tse chesang hangata li hlahisoa ka li-automatic pipe rolling units.

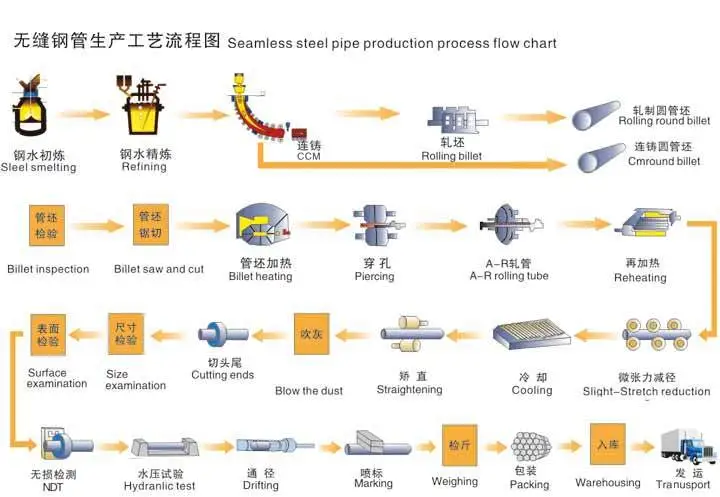

Sekoahelo se tiileng sa tube se hlahlojoa 'me ho tlosoa mefokolo ea holim'a metsi, ho khaoloa ka bolelele bo hlokahalang, ho tsepamisitsoe pheletsong e nang le perforated ea tube e se nang letho, ebe e romeloa sebōping sa ho futhumatsa bakeng sa ho futhumatsa le ho phunya mochine oa ho phunya.E tsoela pele ho potoloha le ho tsoela pele nakong ea mekoti ea ho phunya.Tlas'a tšusumetso ea li-roller le qetello, tube e se nang letho ha e na letho butle-butle, e bitsoang gross pipe.Ebe e romelloa mochineng oa ho roala liphaephe hore o tsoele pele ho bilika.Qetellong, botenya ba lebota bo lekantsoe ke mochini o lekanyang, 'me bophara bo khethoa ke mochini oa boholo ho fihlela litlhoko tse boletsoeng.Tšebeliso ea liphaephe tse tsoelang pele tsa ho roala liphaephe ho hlahisa liphaephe tsa tšepe tse se nang seamless tse chesang ke mokhoa o tsoetseng pele haholoanyane.

Peipi ea tšepe e chesang e rokotsoeng e se nang seamless: tube e chitja e se na letho → futhumatsang → perforation → rolling cross rolling, continuing rolling or extrusion → ho tloswa ha tube → sizing (kapa ho fokotsa bophara) → cooling → billet tube → straightening → hydraulic pressure test (kapa ho lemoha mefokolo) → tšoaea→ ntlo ea polokelo

Mefuta le Maemo

1.Pipe ea tšepe e se nang moeli bakeng sa tšebeliso ea mohaho (GBT8162-1999).Haholo-holo e sebelisetsoang mehaho e akaretsang le mekhoa ea mechine.Lisebelisoa tsa moemeli oa eona (limaraka): tšepe ea carbon, No. 20, le No. 45 tšepe;tšepe ea motsoako Q345, 20Cr, 40Cr, 20CrMo, 30-35CrMo, 42CrMo, joalo-joalo.

2.Liphaephe tsa tšepe tse se nang metsi bakeng sa ho tsamaisa metsi (GBT8163-1999).Haholo-holo e sebelisoa bakeng sa ho tsamaisa liphaephe tsa mokelikeli ho boenjiniere le lisebelisoa tse kholo.Lisebelisoa tsa moemeli (limaraka) ke 20, Q345, joalo-joalo.

3. Lipeipi tsa tšepe tse se nang metsi bakeng sa li-boilers tsa khatello e tlaase le e mahareng (GB3087-1999) li sebelisetsoa ho etsa liphaephe tsa mouoane tse futhumetseng haholo, lipeipi tsa metsi a belang bakeng sa li-boilers tse tlaase le tse mahareng tsa mehaho e sa tšoaneng, liphaephe tsa mouoane tse futhumetseng, liphaephe tse kholo tsa mosi, liphaephe tse nyenyane tsa mosi le arch. litene bakeng sa li-boilers tsa locomotive.Lipeipi tsa tšepe tsa boleng bo holimo tsa tšepe tse chesang tse kolobisitsoeng le tse huleloang ka serame (tse phuthetsoeng) bakeng sa liphaephe.Lisebelisoa tsa moemeli ke No. 10 le No. 20 tšepe.

4.Lipeipi tsa tšepe tse se nang mocheso bakeng sa li-boilers tse phahameng (GB5310-1995) ke tšepe ea boleng bo phahameng ba carbon, alloy steel le liphaephe tsa tšepe tse sa keneleng mocheso tse sebelisetsoang ho futhumatsa libaka tsa metsi a nang le likhatello tse phahameng le holimo.Lisebelisoa tsa moemeli ke 20G, 12Cr1MoVG, 15CrMoG, joalo-joalo.

5.Liphaephe tsa tšepe tse se nang metsi bakeng sa lisebelisoa tsa manyolo tse nang le khatello e phahameng (GB1479-2000) ke tšepe ea boleng bo phahameng ba carbon structural steel le alloy steel seamless lipeipi tse loketseng lisebelisoa tsa lik'hemik'hale le liphaephe tse nang le mocheso o sebetsang oa -40 ~ 400 ℃ le likhatello tse sebetsang tsa 10 ~ 30Ma.Lisebelisoa tsa moemeli ke 20, 16Mn, 12CrMo, 12Cr2Mo, joalo-joalo.

6.Pipe ea tšepe e sa tsitsang bakeng sa ho phunyeha ha peterole (GB9948-1988).Haholo-holo e sebelisoa ka li-boilers, li-heaters tsa mocheso le liphaephe bakeng sa ho tsamaisa maro a li-petroleum refineries.Lisebelisoa tsa eona tsa moemeli ke 20, 12CrMo, 1Cr5Mo, 1Cr19Ni11Nb, joalo-joalo.

7.Lipeipi tsa tšepe bakeng sa ho cheka ha geological (YB235-70) ke liphaephe tsa tšepe tse sebelisoang ke mafapha a jeoloji bakeng sa ho cheka ha mantlha.Li ka aroloa ka liphaephe tsa ho cheka, li-collar tsa ho phunya, liphaephe tsa mantlha, liphaephe le liphaephe tsa sedimentation ho latela ts'ebeliso ea tsona.

8.Seamless tšepe pipe bakeng sa ho cheka ha motheo oa daemane (GB3423-82) ke phala ea tšepe e se nang seam e sebelisetsoang phala ea ho phunya, molamu oa mantlha le casing bakeng sa ho cheka ha motheo oa taemane.

9.Pipe ea ho phunya oli (YB528-65) ke phala ea tšepe e sa tsitsang e nang le matla a ka hare kapa a ka ntle lipheletsong tse peli tse sebelisetsoang ho cheka oli.Ho na le mefuta e 'meli ea liphaephe tsa tšepe: tse nang le lithapo le tse sa baleheng.Liphaephe tse nang le likhoele li hokahantsoe le manonyeletso, ha liphaephe tse se nang likhoele li hokahantsoe le manonyeletso a lisebelisoa ka ho cheselletsa butt.

10.Coil ea Letlapa la Carbonle liphaephe tsa tšepe tsa carbon-manganese tse seamless bakeng sa likepe (GB5312-1999) ke lipeipi tsa tšepe tse seamless tsa carbon tse sebelisoang ha ho etsoa likepe tsa Sehlopha sa I sa liphaephe tse hananang le khatello, liphaephe tsa Sehlopha sa II tse hananang le khatello, liboiler le li-superheaters.Mocheso o sebetsang oa lebota la phala ea tšepe e se nang seamless ha o fete 450 ° C, 'me mocheso o sebetsang oa lebota la phala ea tšepe e se nang seamless le feta 450 ° C.Lisebelisoa tsa moemeli ke 360, 410, 460 limaraka tsa tšepe, joalo-joalo.

11.Seamless steel pipe bakeng sa koloi halofo ea shaft casing (GB3088-82) ke boleng bo phahameng ba carbon structural steel le alloy structural steel hot-rolled seamless steel pipe e sebelisetsoang ho etsa likoloi tsa halofo ea shaft casings le ho khanna li-axle housing shaft tubes.

12.Pipe ea oli e nang le khatello e phahameng bakeng sa enjene ea diesel (GB3093-86) ke phala ea tšepe e sa batang e sebelisoang ho etsa liphaephe tse nang le khatello e phahameng bakeng sa lisebelisoa tsa ente ea diesel.

13. Pipe ea tšepe e se nang seamless bakeng sa tšebeliso ea meralo (GB/T14975-1994) ke tšepe e sa tsitsang e chesang e chesang (e fetisitsoeng, e atolositsoeng) le liphaephe tse batang tse huloang (tse phuthohileng) tse se nang seamless.

14.Lipeipi tsa tšepe tse se nang seamless bakeng sa lipalangoang tsa mokelikeli (GB/T14976-1994) ke liphaephe tse chesang tse chesang (tse ntšitsoeng, tse atolositsoeng) le tse batang (tse phuthetsoeng) tse entsoeng ka tšepe e sa hloekang e sebelisoang ho tsamaisa maro.

15.Liphaephe tsa tšepe tse se nang moeli bakeng sa li-cylinders tsa khase (GB18248-2000).Haholo-holo e sebelisetsoa ho etsa li-cylinders tse fapaneng tsa khase le hydraulic.Lisebelisoa tsa eona tsa moemeli ke 37Mn, 34Mn2V, 35CrMo, joalo-joalo.

Liphaephe tsa tšepe tse se nang seamless li ka senya sebopeho sa tšepe ea tšepe, ea hloekisa lithollo tsa tšepe, 'me ea felisa mefokolo ho microstructure, kahoo e etsa hore mohaho oa tšepe o teteane le ho ntlafatsa thepa ea mochine.Ntlafatso ena e bonahala haholo-holo ka tataiso ea ho roala, e le hore tšepe e se e sa le isotropic ho isa tekanyong e itseng;li-bubble, mapetsong le ho hlephileng tse entsoeng nakong ea ho tšela li ka boela tsa chesoa tlas'a ketso ea mocheso o phahameng le khatello.

E le phala ea tšepe e se nang seam har'a lipeipi tsa tšepe tse se nang letho, e na le lisebelisoa tse latelang:

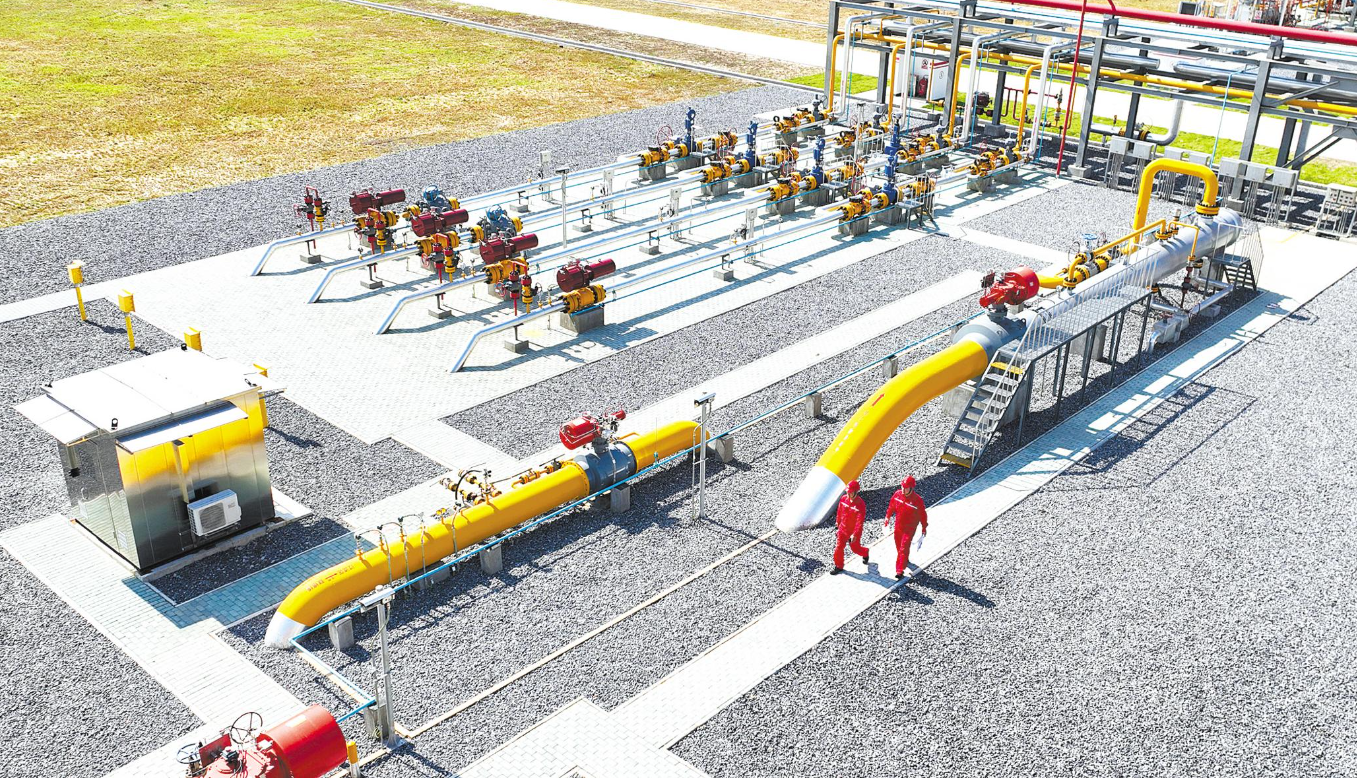

1.Oli le khase: Lipeipi tsa tšepe tse kentsoeng tse chesang li sebelisoa haholo liphaepheng tsa lipalangoang masimong a oli, khase ea tlhaho, khase ea mashala, joalo-joalo, joalo ka liphaephe tsa liliba tsa oli, liphaephe tsa oli, liphaephe tsa oli, lipeipi tsa tlhahiso ea khase e ka tlas'a lefatše, etc.

2.Phepelo ea metsi le khase: Lipeipi tsa tšepe tse chesang tse kentsoeng ka seamless li loketse liphaephe tsa lipalangoang libakeng tse fapaneng tsa phepelo ea metsi le khase, ho tsamaisa moea o hatelitsoeng, mouoane le masimo a mang.

3.Indasteri ea lik'hemik'hale: liphaephe tsa tšepe tse chesang tse kentsoeng li loketse lisebelisoa tse sa tšoaneng tsa lik'hemik'hale, li-reactors, liphaephe tsa lipalangoang, liphaephe tsa liphaephe le masimo a mang.

4.Ho haha Likepe le lifofane: Liphaephe tse chesang tse kentsoeng ka seamless li sebelisoa haholo likamoreng tsa enjene, litsamaiso tsa propulsion le likarolo tse ling tsa ho haha likepe, lifofane le masimo a mang.

5.Tsebeliso e 'ngoe: Liphaephe tsa tšepe tse chesang tse kentsoeng ka seamless li boetse li loketse liaparo tse thibelang ho bola, masimo a kaho, ho etsa mechine, likarolo tsa likoloi, joalo-joalo.

Ho na le mefuta e meraro ea liphutheloana tsa lipeipi tsa tšepe: ho kopanya, litebele, li-bundling tse nang le oli kapa li-boxing tse nang le oli.Hape ho latela litlhoko tsa bareki.

Khamphani ea rona e na le libaka tsa polokelo tse kholo ho pholletsa le China, e nang le lethathamo le lekaneng la thepa le potoloho e khuts'oane ea ho tsamaisa thepa.Ka lilemo tse ngata tsa boiphihlelo ba ho romela thepa e kopantsoeng ka ntle, re na le liphutheloana tse tloaelehileng le Melao ea Lipalangoang bakeng sa ho tsamaisa thepa ea maqephe, e le ho sireletsa tšireletso ea thepa ea hau ka har'a likepe ka tsela e pota-potileng.E sebetsa ho lijana le thepa e ngata.

Hobaneng u khetha Lishengda Trading Co?

1. Konteraka ea hlomphuoa 'me mokitlane oa bolokoa.

2. Theko ea tlhōlisano e nang le boleng bo botle haholo.

3. Sehlopha sa litsebi tsa ho romela thepa ka ntle.

4. Sebaka se loketseng sa lipalangoang.

5. Nako e khutšoanyane ea thomello.